K2 Pure Solutions Chemical Processing Facility

Pittsburg, CA

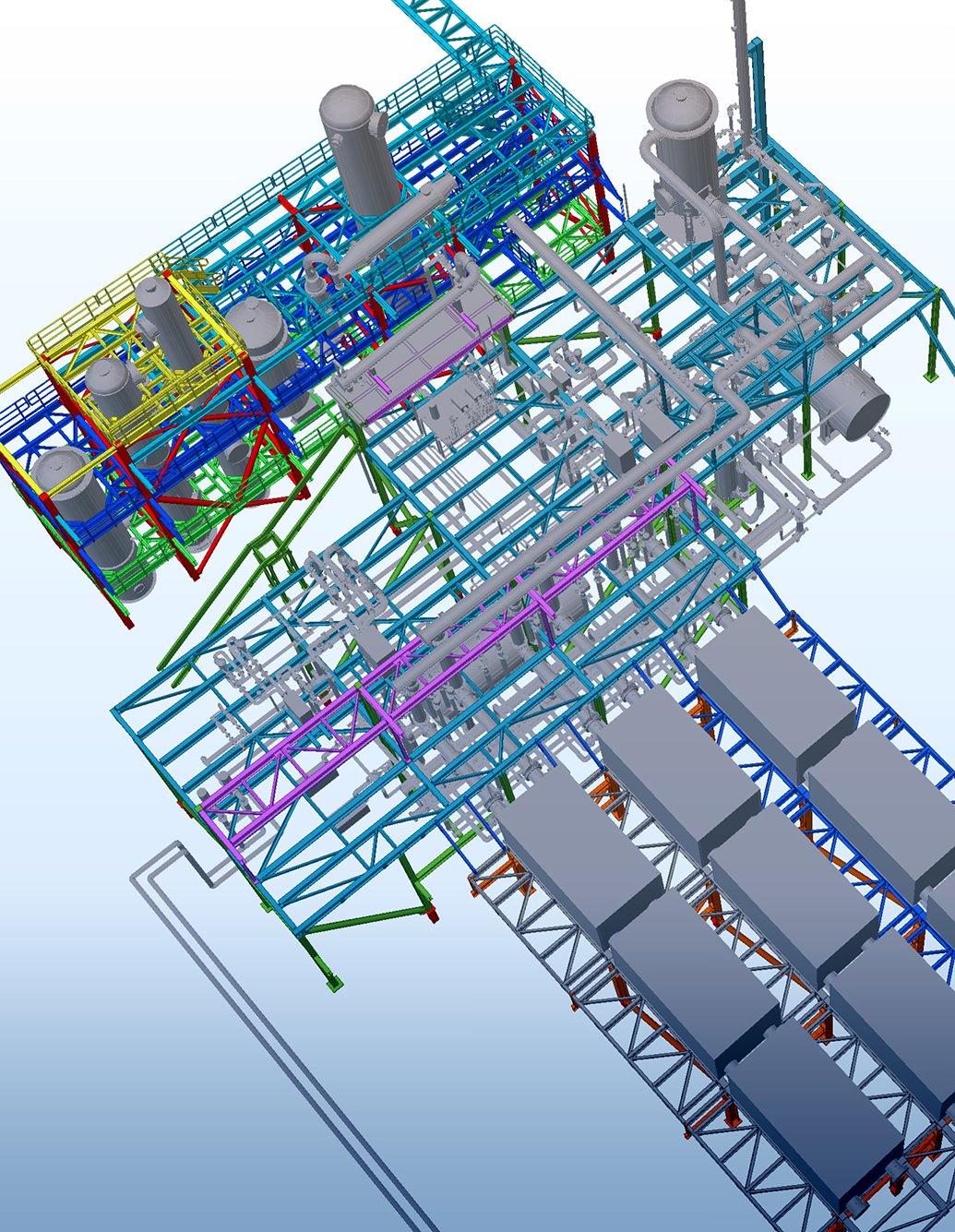

Situated on a site consisting of variable land fill over a tidal marsh, and constructed over 100 years ago for a former chemical manufacturing facility, the new K2 Pure facility is a highly complex, compartmentalized chemical processing plant. Incorporating multiple types of process equipment, vessels, and tanks, the interconnected piping and utilities cover almost 13 acres. New structures include five metal buildings totaling 35,000 square feet, five steel multi-level process area platforms, containment area, tank farms, storage areas, pipe racks and conveyor supports that support literally miles of piping. All steel structures are hot-dip galvanized, and foundations and containment areas were protected from corrosion using epoxy coatings and special designed concrete mixes.

Quick Facts

- Size: Confidential

- Architect: Confidential

- “Salt to Bleach” process - A cargo ship is unloaded every three months at the site along the Sacramento River delta. Raw salt ore is moved by a mobile conveyor system from the dock to a bermed containment area lined with EPDM membrane where the salt is melted into a 30% brine solution. Brine is then processed and fed into an electrolyzer unit that separates chemical components of chlorine, hydrogen and other by-products. Bleach and Hydrochloric Acid are two of the commodities produced by the plant.

- Construction Cost: Confidential

- Contractor: Confidential

- Integrated Project Delivery and Integrated Steel Design was used for the steel design with a 12 week procurement to steel erection timeframe. The project delivery was design-build with a GMP on a fast track schedule.

Photo credit: Buehler Engineering, Inc.